Description

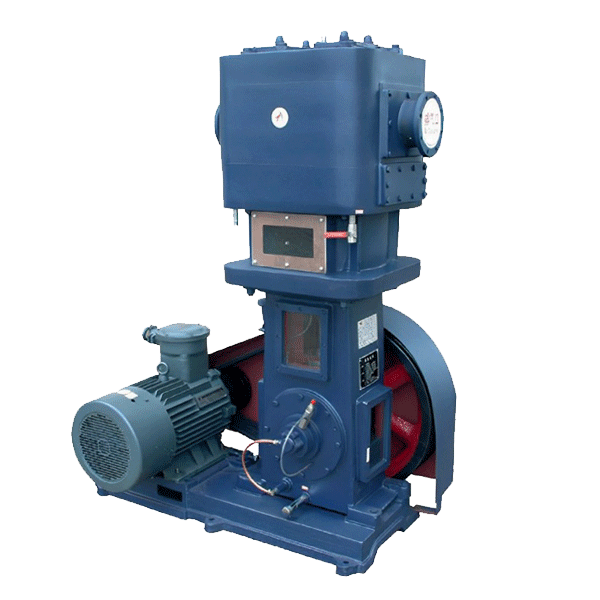

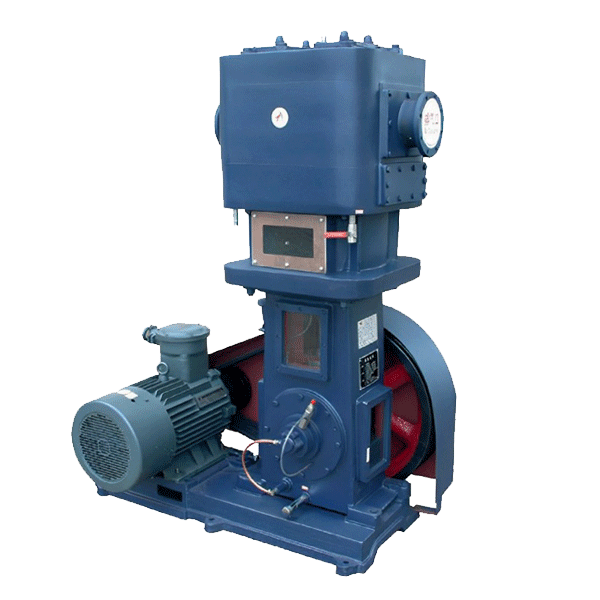

The WL and WLW series vertical (oil-free) reciprocating vacuum pumps are national major new products. Compared with the W and WY series horizontal reciprocating vacuum pumps, they have the following advantages:

1、No oil lubrication, can achieve a clean vacuum environment;

2、1/3 lower power consumption and 2/3 less footprint;

3、The axial arrangement of the air valve makes it easy to operate and maintain, and has a long service life;

4、Eliminated the inferior transverse wave vibration, resulting in low vibration and low noise.

The WLW series vertical oil-free reciprocating vacuum pump is equipped with two inflation chambers between the cylinder and the body, one inert gas inflation chamber and one recovery gas inflation chamber. When removing flammable, explosive, and toxic gases, inert gas can be filled to prevent air (combustion aid) from leaking into the cylinder, thus avoiding accidents; When gas needs to be recovered, the recovered gas can be filled to ensure the purity of the recovered gas.

application area

This series of vertical (oil-free) reciprocating vacuum pumps is widely used in vacuum conveying, refining, distillation, concentration, adsorption, drying and other industries such as pharmaceuticals, pesticides, chemicals, and food.

Technical Parameter

Performance parameters

Type |

Pumping speed (L/S) |

Pressure limit (Pa) |

Revolution (rpm) |

Electrical machinery |

Caliber of air inlet and outlet(mm) | (°C )

Pump temperature |

| Type | (KW)

Power |

| WLW-50 | 50 |

| 270 | Y132M1-6 | 4 | 0)50 |

|

| WLW-70 | 70 |

| 380 | Y132M2-6 | 5.5 | 050 |

|

| WLW-100 | 100 |

| 350 | Y160M-6 | 7.5 | 0100 |

|

| WLW-150 | 150 |

| 310 | Y160L-6 | 11 | 0125 |

|

| WLW-200 | 200 | 2000 | 310 | Y180L-6 | 15 | 0125 | w40 |

| WLW-300 | 300 |

| 250 | Y200L2-6 | 22 | 0160 |

|

| WLW-400 | 400 |

| 250 | Y225M-6 | 30 | 0160 |

|

| WLW-600 | 600 |

| 240 | Y280S-6 | 45 | 0250 |

|

| WLW-1200 | 1200 |

| 260 | Y315M-6 | 90 | 0320 |

|

Working Principle

The WLW series is a single cylinder, single stage, double acting piston pump

1、Mechanical transmission components: driven by a motor through a V-belt, the crank slider mechanism is driven to perform reciprocating motion, and the slider (crosshead) transmits the reciprocating motion to the piston through the piston rod.

2、Suction and exhaust components: The piston groove is equipped with expansion rings, guide rings, and piston rings, which move back and forth in the cylinder to form the expansion and compression of gas inside the cylinder. The suction and exhaust actions are completed through axially arranged intake and exhaust valve groups.

3、Auxiliary functional components: The lubricating oil in the crankcase lubricates the moving parts through splashing oil, and the upper cooling water carries away the heat generated by gas compression. The piston rings in the cylinder are made of F4 self-lubricating material, which does not require additional lubrication.

4、Packing sealing components: divided into ordinary and special types. The ordinary packing sealing material uses polytetrafluoroethylene packing or fluororubber skeleton oil seal.

Special packing seal: A packing cylinder has been added, specifically designed for flammable and explosive gases (such as CO, dry gas, methane, and other gases with high environmental requirements). When in use, nitrogen gas with a certain pressure and flow rate (selected according to the process conditions) is introduced. After two throttling cycles, it mixes with the working fluid that leaks into the mixing chamber and is led out of the system, thereby avoiding the danger of working fluid gas leakage into the environment and preventing air from entering the cylinder to pollute the raw materials.

5、Spacer: To prevent material leakage and contamination of the lubricating oil in the crankcase caused by the failure of packing components, a spacer component is installed to completely isolate the contact path between the overcurrent part and moving parts, ensuring absolute oil-free vacuum system.Especially suitable for environments such as exhaust gas recovery where materials have general corrosiveness, strong sensitivity to engine oil, or require extremely high cleanliness.

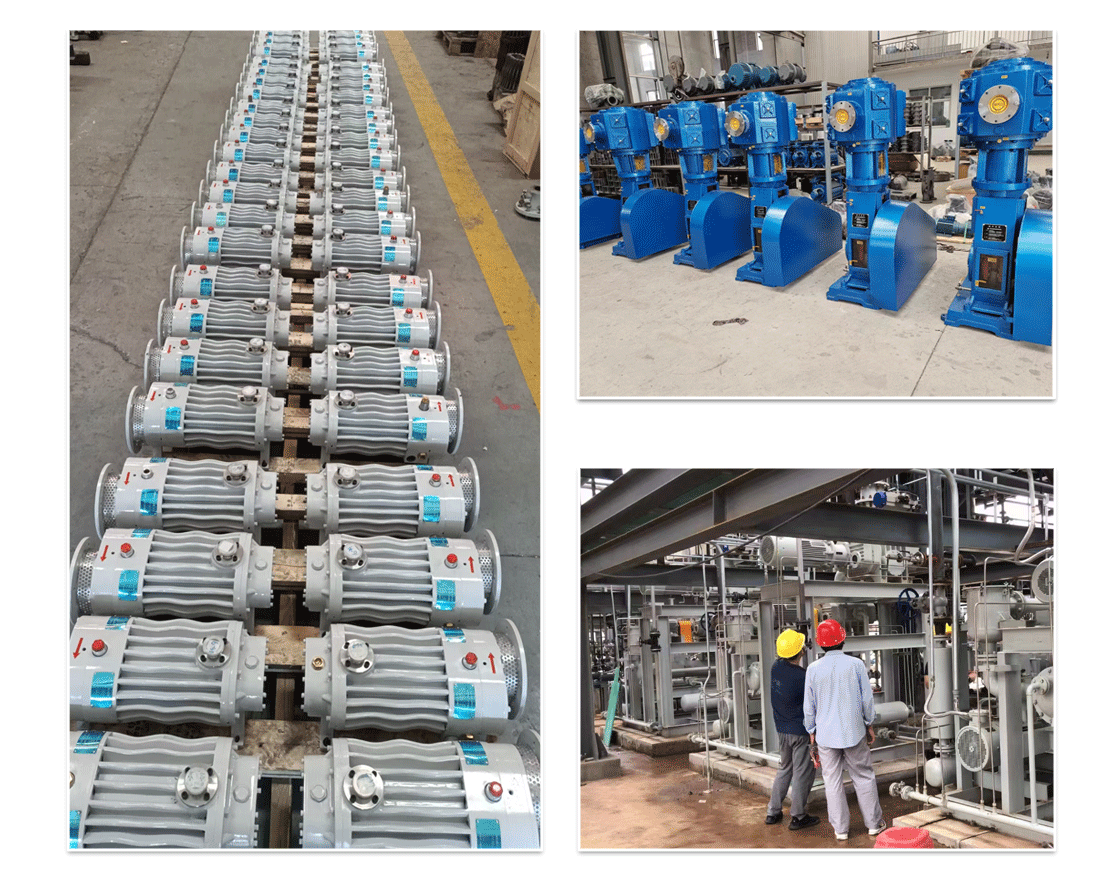

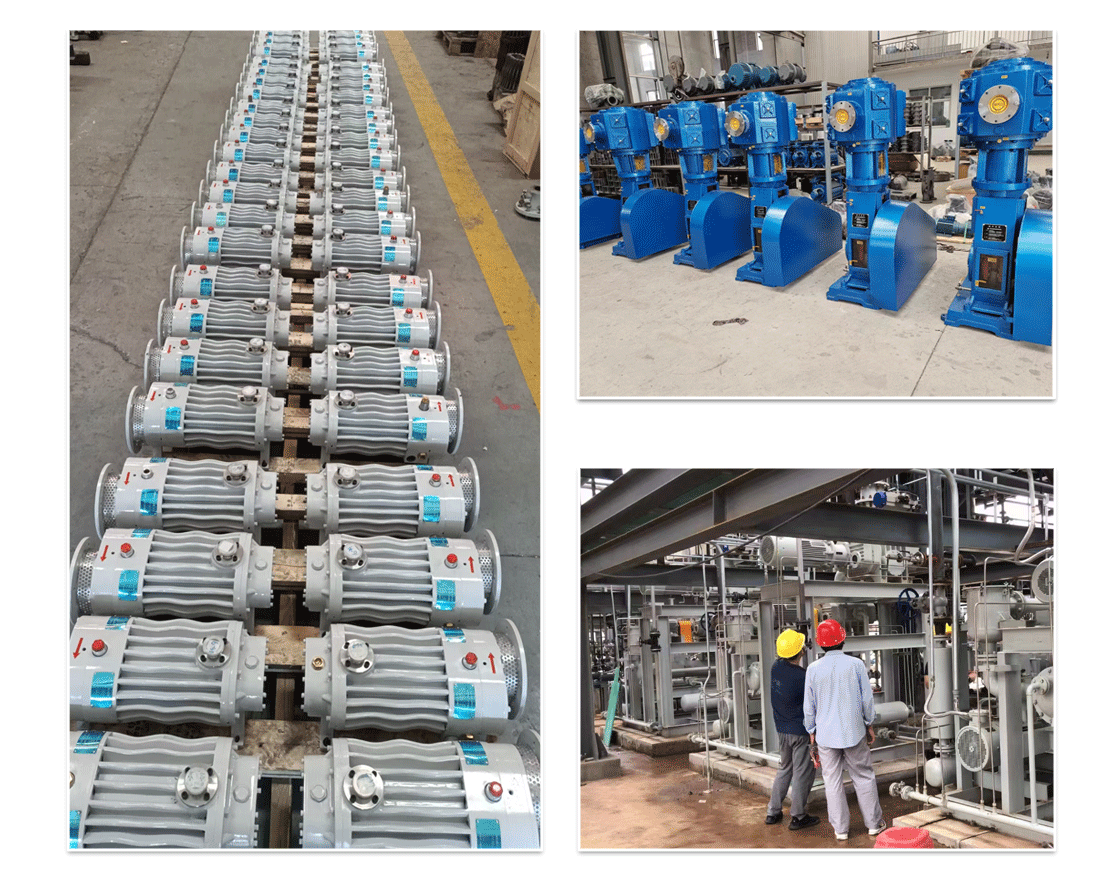

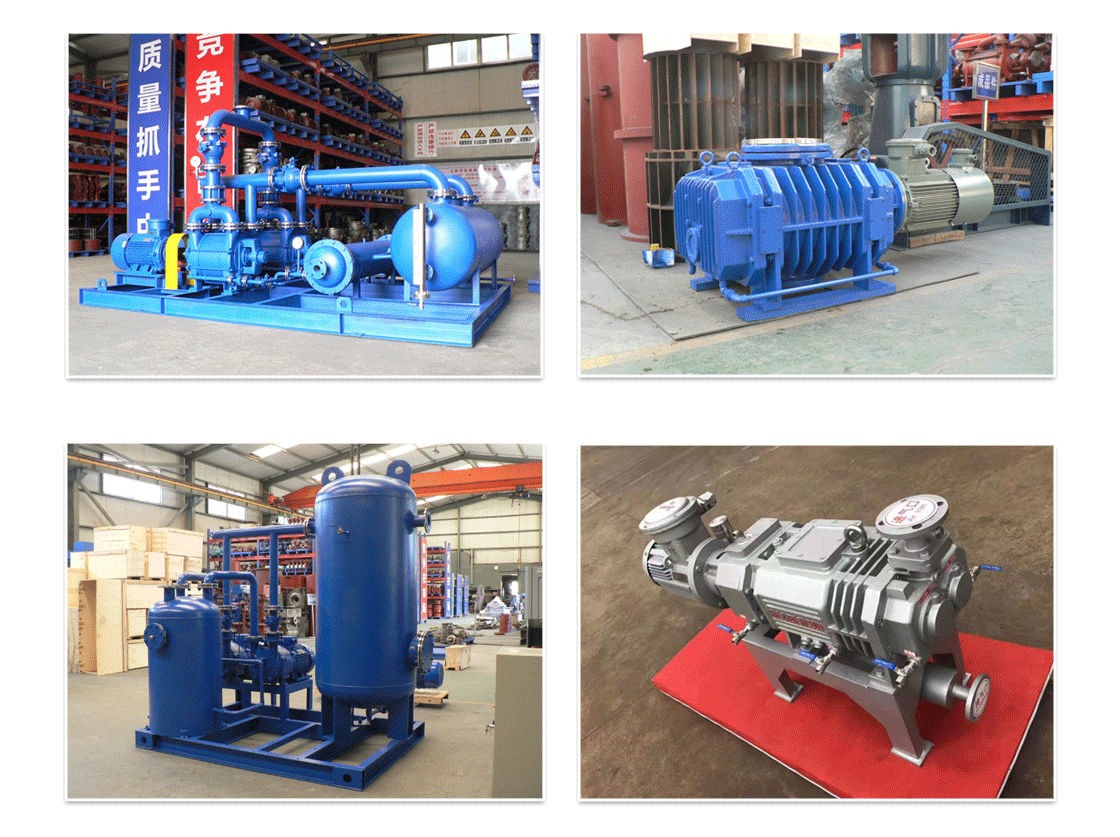

Factory Shooting

Workshop shooting, complete equipment, and rich production experience

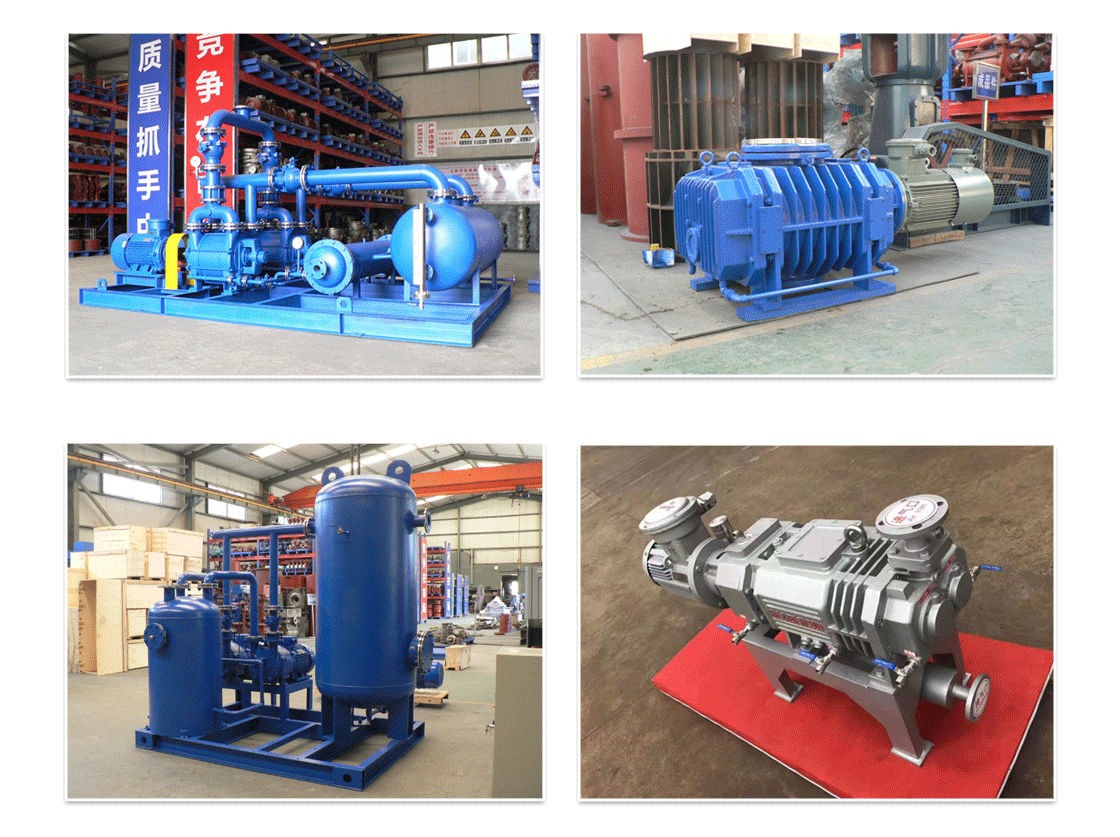

Authoritative Certificate

Strong technical strength, excellent equipment, and products strictly managed in accordance with the ISO9001 quality system.