The liquid ring vacuum pump, also known as a water ring vacuum pump, is a reliable and efficient solution for various industrial applications. Understanding its working principle can help you appreciate its unique capabilities and diverse uses. Let’s delve into how a water ring vacuum pump operates, its internal components, and its typical applications.

How Does a Water Ring Vacuum Pump Work?

The operation of a water ring vacuum pump is based on a sophisticated mechanism that leverages the properties of liquid to create a vacuum. Here’s an in-depth explanation of its functioning:

1. Operation Liquid and Rotary Motion: The pump operates by using an operation liquid, typically water, which is circulated by a rotating impeller. This liquid is crucial for the pump’s displacement of gases.

2. Eccentric Arrangement of the Impeller: The impeller is mounted off-center within a cylindrical chamber. When the pump is not in use, the lower half of the chamber is filled with the operation liquid.

3. Formation of the Water Ring: As the pump starts, the impeller’s movement generates a centrifugal force that propels the liquid against the inner surface of the cylindrical chamber, forming a ring of liquid. This action creates a space in the center of the chamber.

4. Gas Inlet and Compression: The central space, or void, functions as a suction area, pulling in gases from the connected system. As the impeller continues to turn, the void’s size decreases, compressing the gases. The compressed gases are then either expelled directly from a single-stage pump or transferred to a subsequent stage in a multi-stage pump design.

5. Multiple Roles of the Operation Liquid: The operation liquid in the water ring vacuum pump serves several key functions:

Cooling: It absorbs the heat produced during the compression process, helping to cool the pump.

Handling Liquids and Vapors: It can manage any liquids or vapors that may be present in the gas stream.

Sealing: It acts as a seal between the impeller and the chamber wall, ensuring there is no backflow of gases.

This design enables the water ring vacuum pump to handle a variety of challenging conditions, including applications in the food processing, petrochemical, and plastics industries, where it can manage wet, humid, and dirty environments with high temperatures and heavy vapor loads.

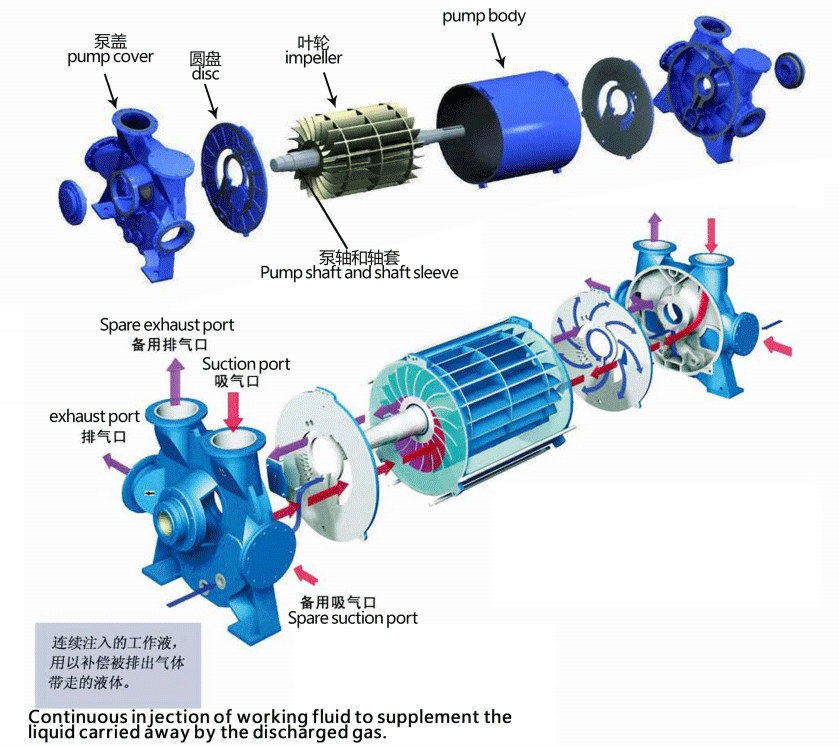

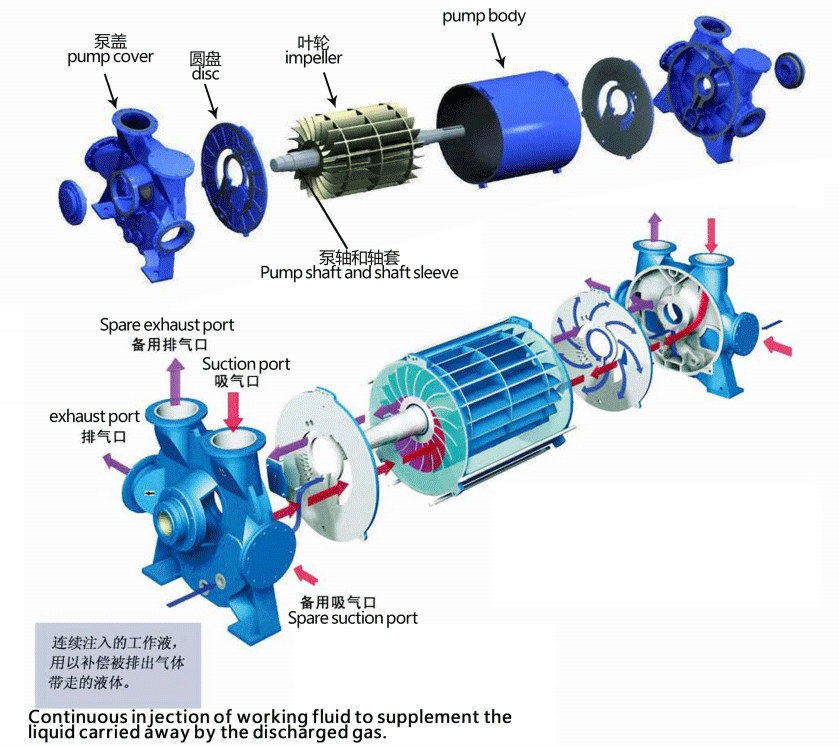

Inside of Liquid Ring Vacuum Pumps

The internal components of a liquid ring vacuum pump are designed to facilitate its unique working principle. Here’s a closer look at these components:

Impeller: A rotating disk with blades that throw the liquid against the pump chamber walls, creating the water ring.

Pump Chamber: A cylindrical housing that holds the water and allows the impeller to rotate within it.

Inlet Valve: Allows air or gas to enter the pump when the cavity expands.

Exhaust Valve: Releases the compressed air or gas when the cavity contracts.

Suction and Discharge Ports: Connect the pump to the system where the vacuum is required.

Function of Water Ring Vacuum Pump

The function of a water ring vacuum pump is multifaceted, driven by its unique design and the behavior of the liquid ring that it creates. At its core, the pump serves to generate a vacuum by displacing the liquid within its chamber, which in turn facilitates a range of industrial processes. The liquid, often water, is central to the pump’s operation as it performs several critical functions simultaneously.

Firstly, the liquid ring vacuum pump is adept at creating a vacuum by expanding and contracting the space within the pump chamber as the impeller rotates. This vacuum is essential for a multitude of applications, such as drying, degassing, and distilling, where the removal of air or other gases is paramount. Secondly, the pump is designed to handle gases that are moist or contain particulates, which is made possible by the liquid ring that acts as a barrier, preventing contact between the gas and the moving parts of the pump. This feature not only protects the pump from damage but also ensures that the process remains contamination-free.

Moreover, the liquid ring serves a vital role in heat dissipation. As gases are compressed, heat is generated, but the liquid ring absorbs this heat, preventing thermal damage to the gases being processed and maintaining the pump’s operational efficiency. Additionally, the pump’s ability to handle liquids and vapors makes it particularly suitable for applications where other types of vacuum pumps might fail due to corrosion or clogging.

In essence, the function of the water ring vacuum pump extends beyond mere vacuum generation. It is a robust and versatile piece of equipment that can operate continuously in harsh environments, manage a variety of gas and liquid mixtures, and maintain process integrity across a wide spectrum of industrial uses. Its reliability and the richness of its operational capabilities make it an indispensable tool in sectors as diverse as chemical processing, food production, and pharmaceutical manufacturing.

Characteristics Of Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps are renowned for their exceptional performance and durability in a variety of industrial applications. These pumps are designed to handle demanding conditions with ease, offering several key characteristics that make them an ideal choice for a wide range of industries.

Acceptance of Carryover: Liquid ring vacuum pumps are capable of handling a wide range of impurities such as soft solids, moisture, slugs, and chemicals without causing any damage to the pump. These impurities are simply washed out through the pump’s discharge, ensuring smooth operation and minimal maintenance requirements.

Cool and Quiet Operation: The pump operates at a low temperature due to the circulation of the sealing water inside the pump body. This design feature results in a relatively quiet operation, with noise levels not exceeding 85 dBA, making it suitable for environments where noise pollution is a concern.

Continuous Operation at Any Vacuum Level: Liquid ring vacuum pumps can operate continuously and uninterrupted at any vacuum level, from 29 inches Hg to atmospheric pressure. This versatility allows them to adapt to various process requirements and ensures uninterrupted operation.

Ease of Maintenance and Longer Pump Life: The robust construction of liquid ring vacuum pumps, featuring a single moving part (the rotor), mounted on a shaft supported by bearings designed for long service life, results in less wear and simpler, more affordable maintenance. This characteristic extends the pump’s lifespan and reduces downtime due to maintenance issues.

Environmental Friendliness: These pumps do not require oil changes, filters, oil pans, or condensers, thus eliminating oil contamination and discharges to sewers. This environmentally friendly design contributes to cleaner plant rooms and reduces the carbon footprint of industrial operations.

Typical Applications

Liquid ring vacuum pumps find applications across a wide range of industries due to their robust design and versatile performance. Some typical applications include:

Chemical Industry: Used for distillation, drying, and degassing processes.

Food and Beverage: Ideal for vacuum evaporation, concentration, and bottling lines.

Pharmaceuticals: employed in vacuum drying and mixing processes.

Pulp and Paper: Utilized in stock preparation and vacuum pressing.

Petroleum and Gas: Used for degassing and condensation processes.

FAQ

How does a liquid ring vacuum pump handle impurities in the gas stream?

Answer: A liquid ring vacuum pump is designed to handle impurities such as soft solids, moisture, slugs, and chemicals. These impurities are washed out through the pump’s discharge without causing damage to the pump, ensuring smooth operation and minimal maintenance.

Is a liquid ring vacuum pump noisy during operation?

Answer: The liquid ring vacuum pump operates relatively quietly due to its design, which includes the circulation of sealing water that helps cool the pump. Noise levels typically do not exceed 85 dBA, making it suitable for noise-sensitive environments.

Can a liquid ring vacuum pump operate at different vacuum levels?

Answer: Yes, a liquid ring vacuum pump can operate continuously at any vacuum level, ranging from 29 inches Hg to atmospheric pressure. This flexibility allows it to cater to various process requirements without interruption.

How easy is it to maintain a liquid ring vacuum pump, and what is its expected lifespan?

Answer: The liquid ring vacuum pump is easy to maintain due to its simple design with only one moving part, the rotor. The robust construction and long-lasting bearings contribute to a longer pump life and reduce maintenance costs and downtime.

Is a liquid ring vacuum pump environmentally friendly?

Answer: Yes, the liquid ring vacuum pump is environmentally friendly as it does not require oil changes or filters, and it does not produce oil contamination or discharges. This design helps maintain a clean plant environment and reduces the environmental impact of industrial operations.